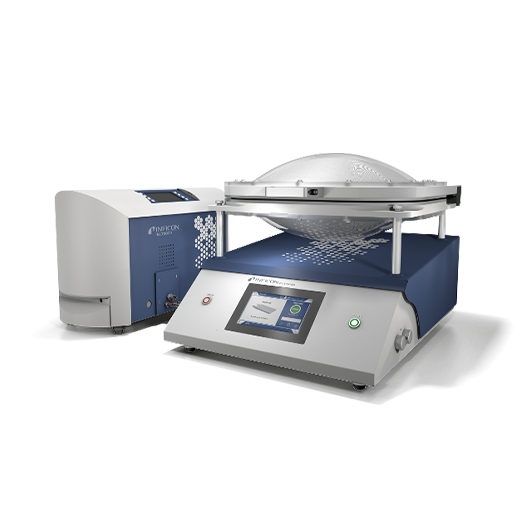

ELT3000 Battery Leak Detector

- Lightweight and compact

- For battery cells

- Mass spectrometer

- Leak detector dedicated to batteries that can directly detect electrolyte.

Basic Specs.

| Min. detectable leak rate | 1 × 10-6 mbar·I/s (Helium equivalent leak rate) |

|---|---|

| Measurement range | 3 digits |

| Leak display unit |

Mbar·l/s, atm·cc/s, Pa·m-3/s |

| Detection sensor | Quadrupole mass spectrometer (Cathode x 2) |

| Measurement mode start-up time |

180 s |

| Serial interface | USB2.0, M12 (for connecting to I/O1000), RJ45 (for network connection) |

| Interface via I/O1000 module | Digital input x 10, Digital output x 8, RS232 |

| Ambient temperature | 10 to 40 ℃ (50 to 104 °F) |

| IP ratings | IP20 |

| Gas detection unit dimensions (W x H x D) |

610 mm × 300 mm × 380 mm (24 in × 12 in × 15 in) |

| Control unit dimensions (W x H x D) |

700 mm × 540 mm × 250 mm (27.6 in × 13.7 in × 6.4 in) |

| Weight | 65 kg(144.5 lbs) |

| Multi-language | English, German, Korean, Chinese, Japanese |

Features / Functions

Ensuring reliable battery life

Mass spectrometer technology enables leak detection that is 1,000 times more accurate than conventional methods and provides up to 10 years of battery cell life.

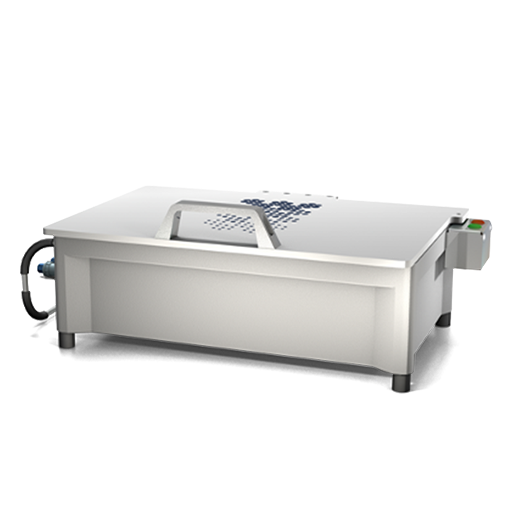

Testing possible for a wide variety of works

The ELT3000 system is suitable for square, round, and pouch cells.

Battery cells of different shapes can be inspected with the ELT3000.

Easy operation and system integration

The inspection procedure is simple, and the touch screen makes using the ELT3000 easy and intuitive. No costly training courses required.

The system can be fully integrated into automated manufacturing processes.

High efficiency

The two test chambers are designed to simultaneously test multiple cells in one test cycle.

Combined with short cycle times, the system enables quick delivery of inspection results.

Main applications

- Manufacture of smartphones and tablets

- E-mobility industry

ELT3000 - Incorporating sustainability

Leak testing of battery cells ensures long battery life and avoids unnecessary consumption of valuable resources used in battery manufacturing.

Leak testing also prevents harmful battery electrolytes from being released into the environment.