Abnormal noise detection system In-line tester

MV-6000B

Edge & Function

Can respond to several abnormal noises through compound judgments.

Single and compound judgments on basis of judgment criteria of 8 kinds allows for high precision testing.

Equipped with I/O port for linking with external controller

Multiplexer (optional) available for switching sensors

Construction of hammering test system possible by linking with impactor

RS232C output standard equipment for data management.

VGA port x 1: Monitor display

USB port x 2: Keyboard /mouse operation / Data storage media (HDD, Flash memory etc)

LAN port x 1: Ethernet connection

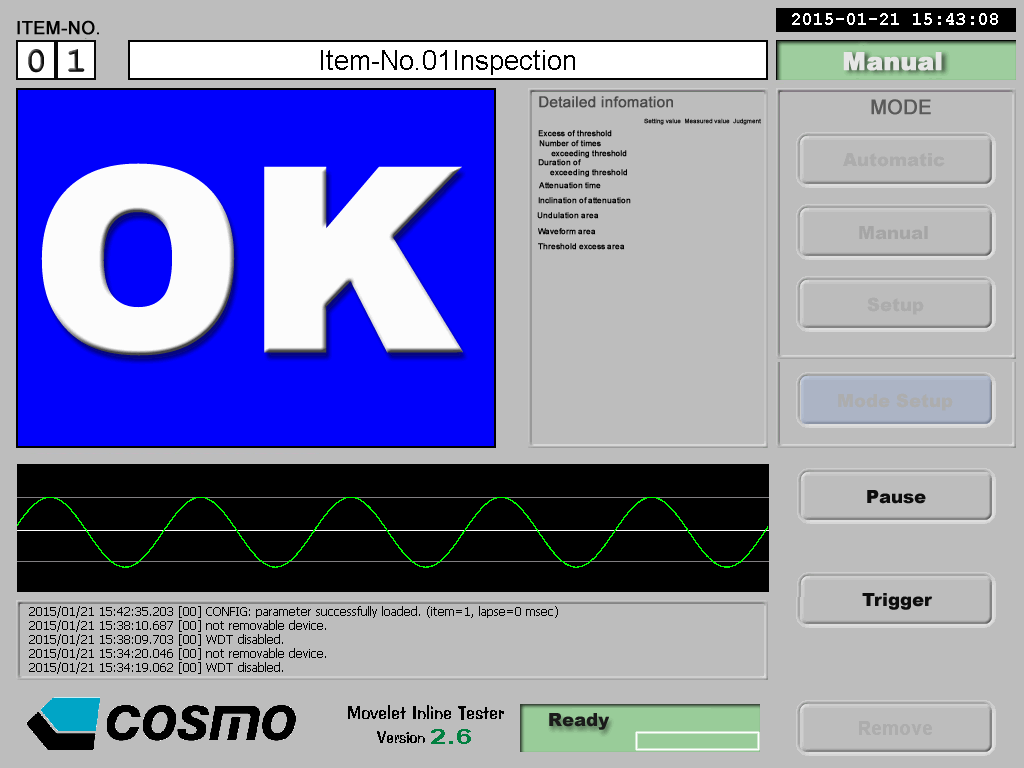

・Determination display (OK/NG)

・Item number/name display

・Waveform display (displays inputted waveform)

・Status display

・Mode selection (automatic/manual/set)

・Display details of determination

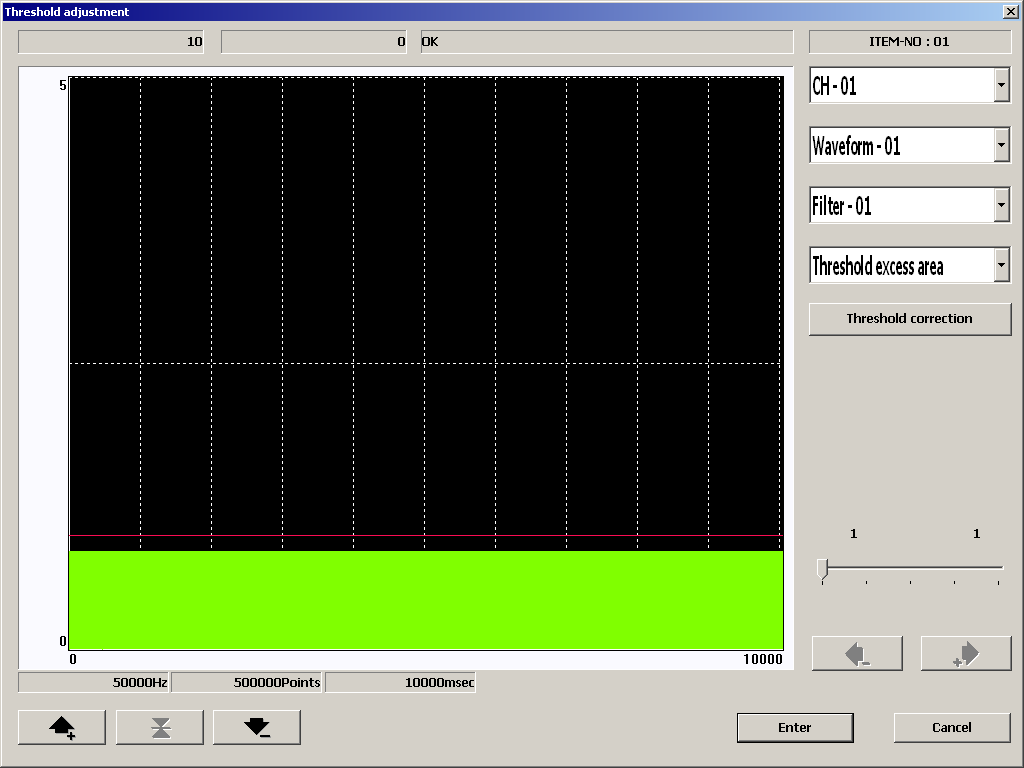

・Display analyzed waveform

・Choose display waveform (can choose from newest 8 data)

・Threshold correction

・Automotive

power seat,seat rail,air-conditioner blower,power sunshade,starter,power door mirror,power window,wiper motor,engine(four-wheel and two-wheel drive),horn,fan,brake pad,car audio,power steering,transaxle motor

・Others

golf club(impact sound),crack in ceramics/sintered metal,buildings materials(crack,peeling),connector clicking sound

・Seat (Automatic / Manual transmission car) noise inspection

Operating noise inspection when moving or reclining the seat forward / backward.

・Tunnel and concrete hammering inspection

Crack, flaw and deterioration inspection of the tunnel, concrete, mortar and so on.

Cosmo offers the analysis trial for your tested part in order to feel how Movelet really works.

By having the sample Pass/Fail examples of tested parts, we will be able to perform the analysis trial at your site or Cosmo premise.

Please feel free to contact the nearest Cosmo office if you have any questions.

Spec

| Items | Specifications | |

|---|---|---|

| Model | MV-6000B | |

| 機能仕様 | Number of registered items | Up to 99 items |

| Sampling Frequency | 10000Hz/20000Hz/25000Hz/40000Hz/50000Hz/ | |

| Data Acquisition Time | 10msec~60sec | |

| Judgment criteria (judgment methods) | 8 types | |

| Judgment combination | Single judgment/compound judgment of judgment criteria (judgment methods) | |

| Saving data | wav file type (number of saved data depends on sampling data type) | |

| Process status and judgment display | 7-segment display | |

| Interface | Sensor input point | 1CH |

| Sensor input voltage/connector | ±5V BNC connector | |

| USB I/F | USB-A type female: 2 | |

| COM I/F | D-SUB9 pin(male): For data 1(RS-232C) | |

| LAN I/F | Ethernet connector (RJ-45) | |

| CRT I/F | HD-SUB 15 pin (female) | |

| I/O input/output for control | D-SUB 37pin(Female) NPN/PNP available | |

| Power Source | Power connector | Grounded 3P |

| Input power voltage | AC100~240V±10% | |

| Power Consumption | 80VA(MAX) | |

| Peripheral environment | Ambient temperature | 5~40℃ |

| Humidity | 80%RH or less, no dew condensation | |

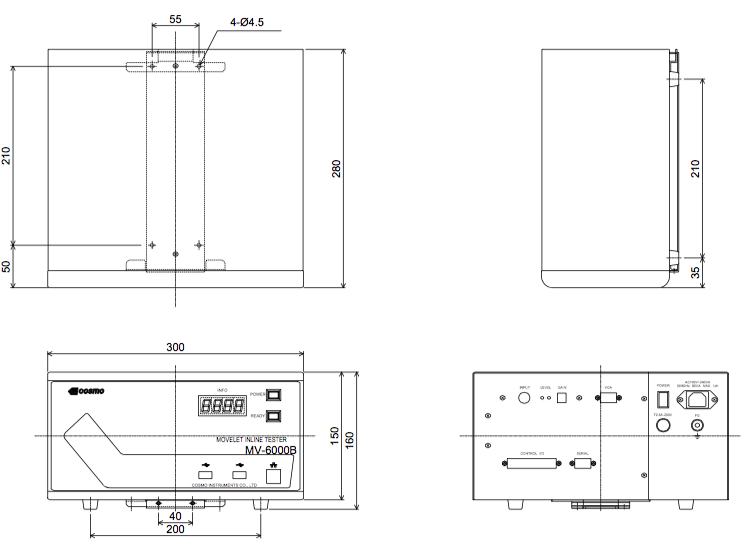

| Structure | Outer dimensions (mm) | 300(W)×160(H)×280(D) |

| Main body mass | approx. 6.7kg | |

| Options | Remote control box RC-30, Multiplexer MVM-60, sound level meter, acceleration pick-up, LAN cable | |

Classification

MV-6000B-①

| symbol | |

|---|---|

| Japanese | J |

| English | E |

Appearance