Volumetric Air Leak Testers Leak Testing System for Small Electronic Components

LZ-3000

Edge & Function

With the two-part index system, a maximum of 60 pieces can be processed, and fully automatically transported, aligned, inspected, checking quality and sorting out bad ones.

With our newly developed micro-volume detection type air leak tester, extremely small gross leak inspections of as small as 2.0mm x 1.6mm are possible.

Spec

| Model |

LZ-3000 |

|||

|---|---|---|---|---|

| Target workpieces |

Small, sealed electronic components |

|||

| Processing capabilities |

Maximum of 60 pieces/minute (1.0 second/piece) |

|||

| Gross leak test system |

Micro-volume detection type air leak tester system |

|||

| Number of air leak testers included: |

8 |

|||

| Air leak tester specifications | Model |

LUV-880-KX03 |

LUV-880-KX05 |

LUV-880-KX2 |

| Minimum workpiece internal clearance volume |

0.3 mm^3 or more |

0.5 mm^3 or more |

2.0 mm^3 or more |

|

| Minimum detectable equivalent price standard leak amount |

1.17×10^-6 Pa・m^3/sec |

5×10^-6 Pa・m^3/sec |

2×10^-5 Pa・m^3/sec |

|

| Target workpiece size |

2.0×1.6 2.5×2.0mm |

2.5×2.0 3.0×3.0 3.2×2.5mm |

3.8×3.8 5.0×3.2 9.5×7.2mm |

|

| Workpiece supply method |

Lined-up supply from part feeder with hopper |

|||

| Workpiece transport system |

Movable pick and place, left to right two-part index |

|||

| Inspection movements | Full-automatic operation |

■ Normal operation, ■ Calibrating operation, ■ Recovery operation |

||

| Manual operation |

■ Individual operation, ■ Calibrating operation, ■ Return to original position, ■ Withdrawing operation |

|||

| Decision processing |

Collection of sorted out defective pieces in collection bucket |

|||

| Self-diagnosis function |

Self-diagnosis of tester malfunction, individual movement malfunction, pressure anomaly, etc. |

|||

| Information output |

Automatic collection of measurement result data on USB memory, RS-232C |

|||

| Environment conditions |

5~40℃ |

|||

| Power Source |

Three-phase 380V and three-phase 200V, 50/60Hz 1.5kW |

|||

| Air pressure source |

0.4MPa or greater 250L/min pipe size: Rc1/2 (PT1/2 internal thread) |

|||

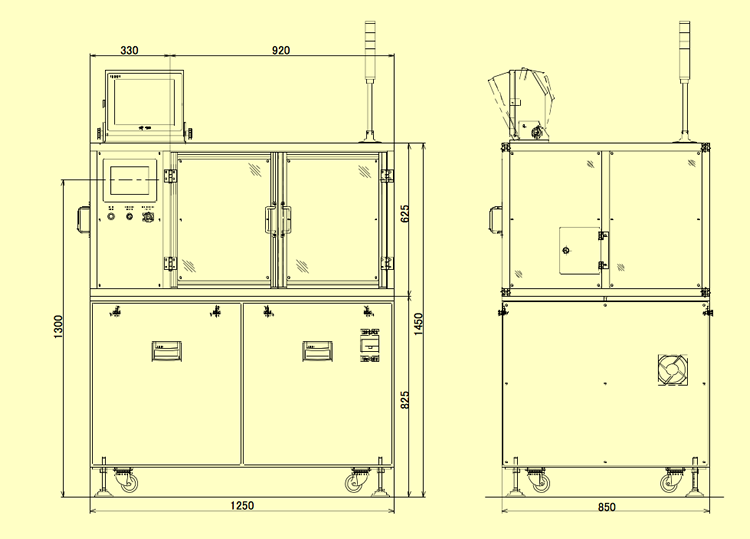

| Outer dimensions |

1250 (W)×1450(Max1890)(H)×850(D) mm |

|||

| Options |

* Compatible with similar workpieces of multiple types * Workpiece supply discharge (online compatible/ career magazine compatible) |

|||

| Documents |

Traceability documents, Operation manual |

|||

Appearance